5 Axis Waterjet Cutting

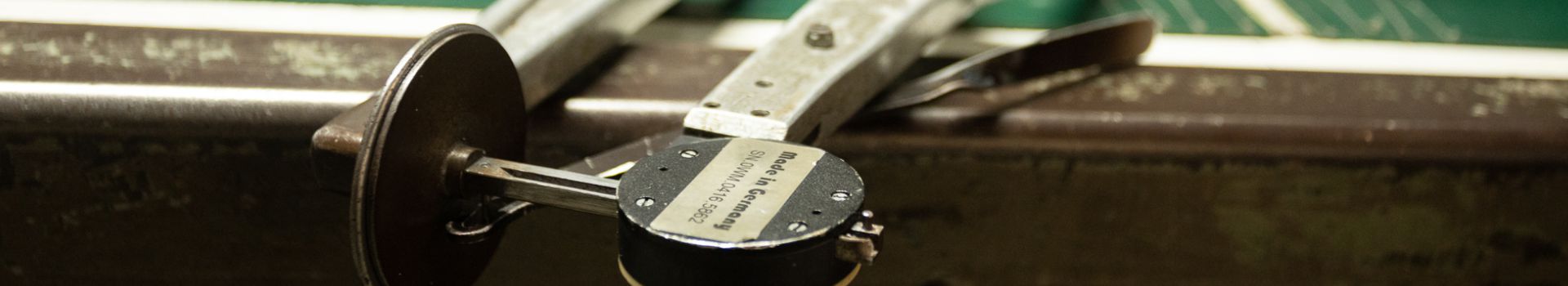

Sondor offers the latest in cutting edge, innovative production. We embrace 5-axis waterjet cutting technology to give optimum performance for precision cuts on challenging material types.

Water jet cutting uses high-pressure water mixed with an abrasive substance, such as sand, to effortlessly cut through foam. CNC waterjet machines speed up and concentrate this process to cut at increasing speeds. Waterjet cutting is preferred when the cut material is likely to be compromised by other heat cutting methods.

Sondor's 5-axis waterjet cutting system is capable of cutting accurately, efficiently, and economically. We are able to combine the technology of waterjet and drilling on the same platform: adding multiple heads or three-dimensional cutting, which increases productivity. Sondor's waterjet cutting technology allows products to be machined efficiently with high accuracy and superior quality, ensuring smooth edges despite challenging compound angles.

Advantages

- Waterjet cutting minimises the damaging effects of heat cutting.

- No distortion, warping or cracking.

- Produces complex shapes with unparalleled precision

- Sondor's 5-Axis cutting machine opens up 3-dimensional cutting abilities at angles from 0° to 45°. This process easily navigates around complex cutting angles and ensures versatility in the fabrication process.

- Up to nine 5-Axis cutting heads can be installed on one cross beam with a single X-Classic controller.

- Unlike laser cutting and traditional cutting methods, Waterjet cutting does not distort or alter the foam structure during cutting.

- Its ability to cut in 3D also allows for cutting a variety of complex shapes not achievable with other methods.

- Waterjet Cutting produces no harmful chemical byproducts (unlike plasma cutting and laser cutting), saving time, money, and is environmentally friendly.

With branches in Cape Town, Durban, Gauteng, Pretoria and Gqeberha, our knowledgeable representatives can advise the right solution for you. Find a branch near you for expert assistance.