Die-Cutting & Gasketing

Foam gaskets are a versatile solution that provides a superior barrier and bonding capabilities for a wide range of products and applications. Sondor manufactures foam gaskets from high quality, cross-linked, closed-cell foam material which are suitable for use in many everyday use applications. Gasketing from Sondor is available in a range of shapes, densities, sizes, and materials. All gasketing is done to customer specifications. Sondor can custom design and die-cut foam gaskets to create a seal that's ideal for your application.

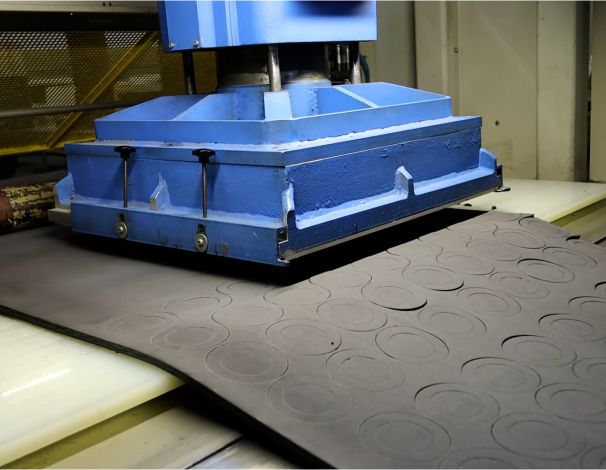

How does Die Cutting Foam work?

Die cutting foam is a process in which foam materials are cut into specific shapes and sizes using specialized blades and dies. The foam material is typically heated or softened in some way to make it pliable and easier to work with. As the foam is pushed between two heated dies, the blades score, slice, or perforate the foam material until the desired shape has been created. The resulting die cut foam can then be used for a wide range of applications, from cushioning and insulation to packaging and gasketing. The precise nature of this process allows for intricate designs to be created from even thin sheets of foam, making it an extremely versatile material for any number of uses. So if you're looking for a way to transform your foam materials into custom shapes and structures, consider die cutting as an easy, effective solution.

Applications

- Foam gaskets can be applied to a wide range of industries, including: Appliance, Automotive, HVAC, Medical, Electronic, and Lighting, to name a few.

- Sealing applications, for example, ventilation, dust and moisture sealing, vibration dampening and waterproofing.

- Weatherproofing: EVA gaskets provide good weathering, U.V., low temperature as well as ageing resistance. This makes them suitable for use in a number of outdoor weatherproofing applications, effectively sealing against unwanted elements.

- Automotive: Sondor's closed-cell gaskets do not need much pressure to create a seal. When you combine this with excellent chemical and oil resistance, you get a well-suited solution for automotive applications, particularly in vehicle interiors.

- Filters, washers, and shaped components for the automotive, electronics and industrial industries

- D.I.Y. applications

- Cushioning and protection of fragile objects

- Mounting

- Insulation

- Noise reduction

- Vibration control

- Electrical absorption

- Fluid restriction

- Weather resistance

Advantages

- Ease of fabrication - cut to almost any shape or size - saving you time, labour costs and minimising waste

- Impregnated foams are available for irregular gaps

- Sondor foams are naturally water repellent. This increases the buoyancy of the material and ensures the gaskets are resistant to mildew and bacteria.

- Sondor foams are also resistant to weather and U.V. deterioration. This makes gaskets an excellent solution in a number of exterior sealing applications.

- Sondor has over 70 years of experience and has branches located nationwide for your convenience.

- All products are supplied according to customer specifications.

- Flame retardant and anti-static grades are available.

With branches in Cape Town, Durban, Gauteng, Pretoria and Gqeberha, our knowledgeable representatives can advise the right solution for you. Find a branch near you for expert assistance.