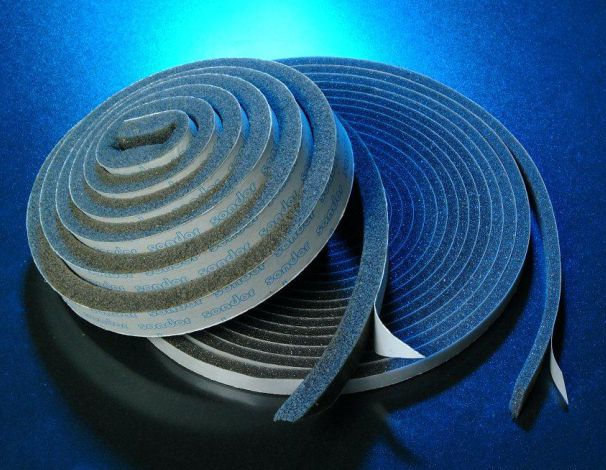

Acryband - Sealing Material

Directions for use:

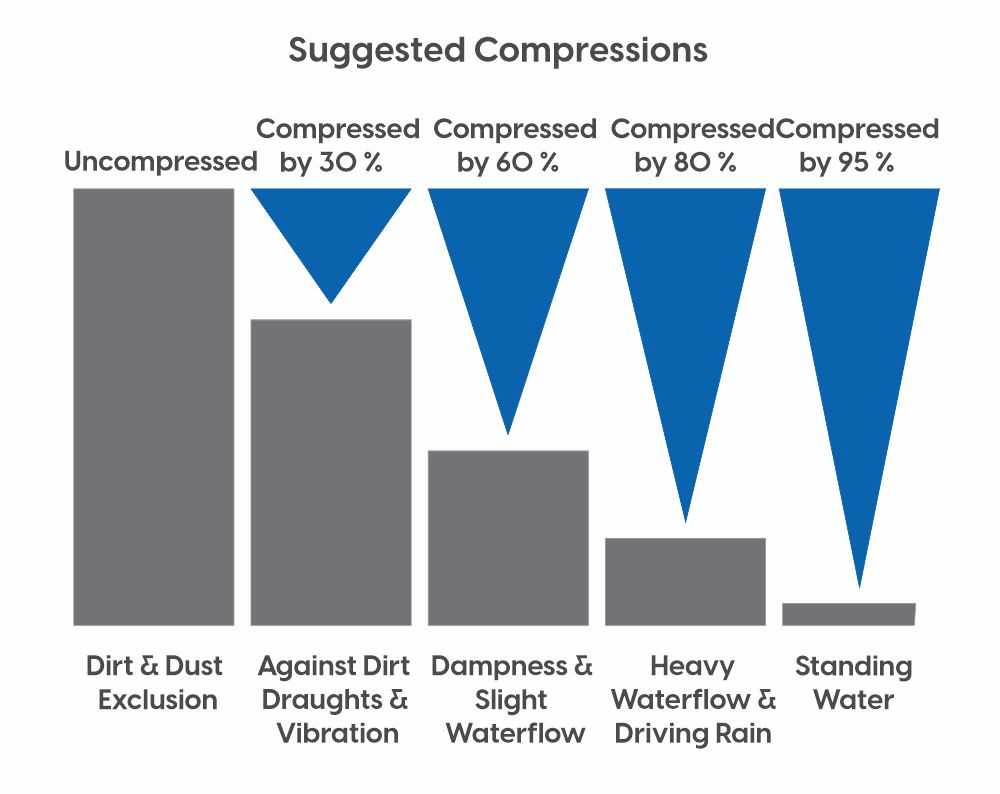

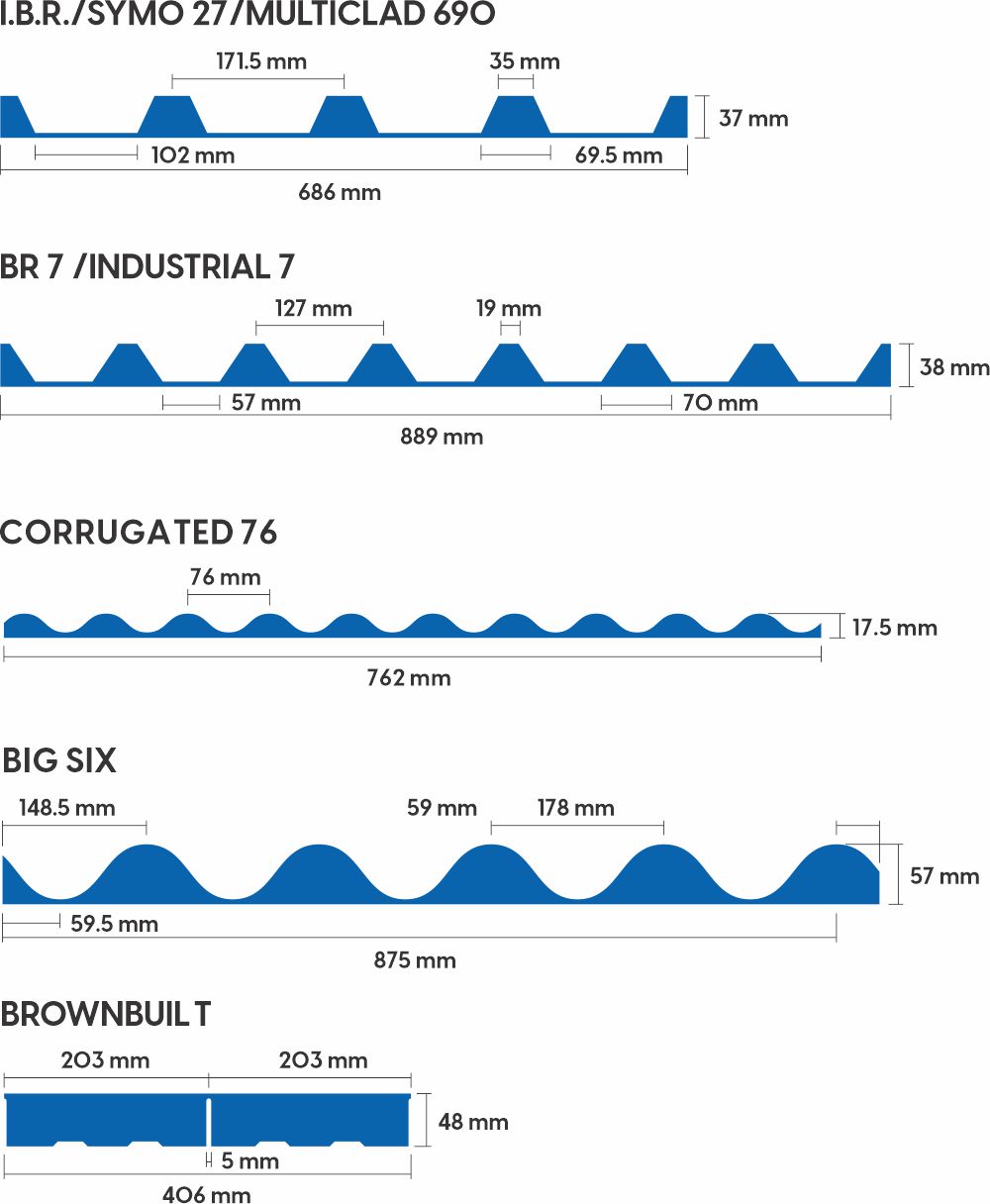

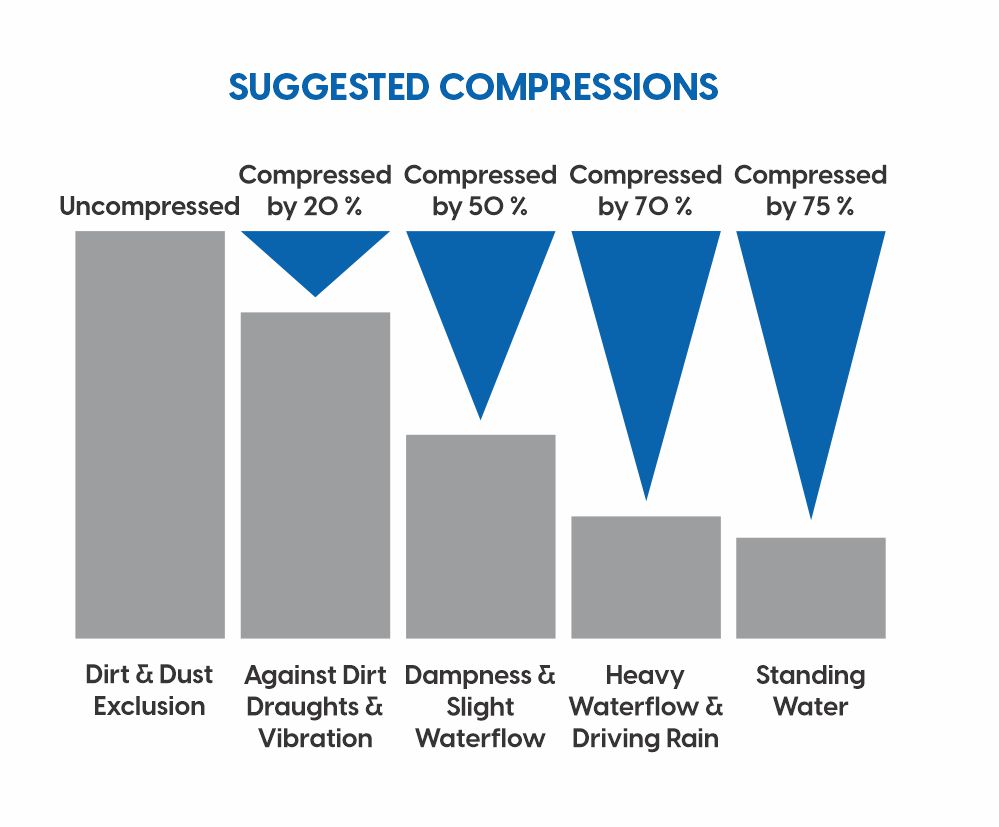

- Dust off area of application and choose an oversize section of Acryband according to your particular needs. See compression chart.

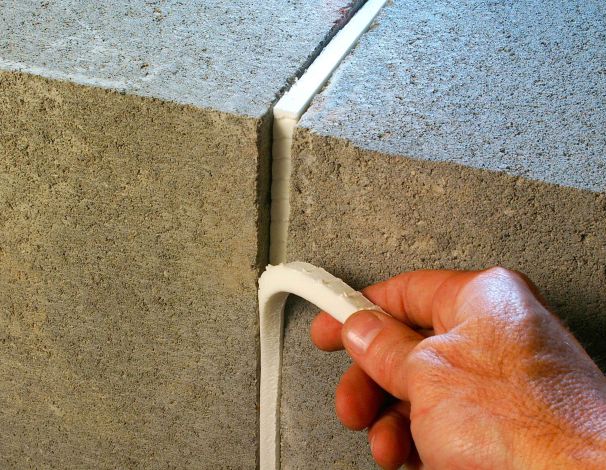

- Compress Acryband and insert into gap. Acryband will expand within minutes to even out all irregularities and produce a completely effective seal.

- Acryband can be supplied with self-adhesive backing on one side if required. In this instance, ensure that the surface is dust free, remove the backing paper and press adhesive side of Acryband to surface as required.

- Acryband is economical and easy to use.

- Expands within minutes of insertion, evening out all irregularities.

- Resistance to adverse weather and temperature conditions makes it an ideal sealing medium for most external applications.

- Needs no primer and is clean to handle.

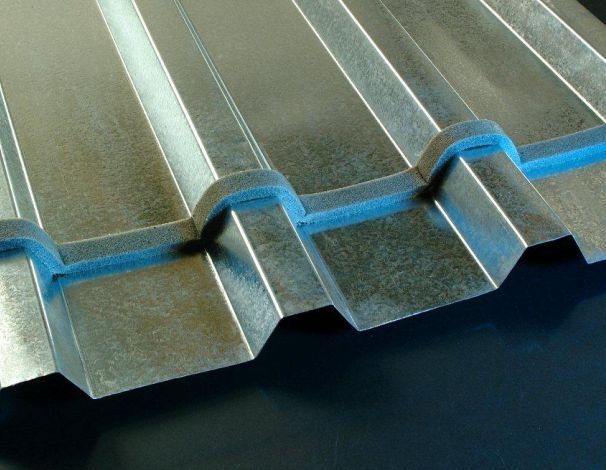

- Suitable for sealing regular and irregular gaps against dust and draughts.

- Used by window & door contractors and in log cabin & timber house construction.

- Dust, dirt and waterproof sealing in motor vehicle manufacturing.

- D.I.Y. applications.

- Weathering: Retains elasticity and sealing qualities (if compressed).

- Is resistant to ageing (if not directly exposed to UV rays for an extended period of time).

- Temperature Range: Remains permanently resilient and effective from -20°C to +120°C.

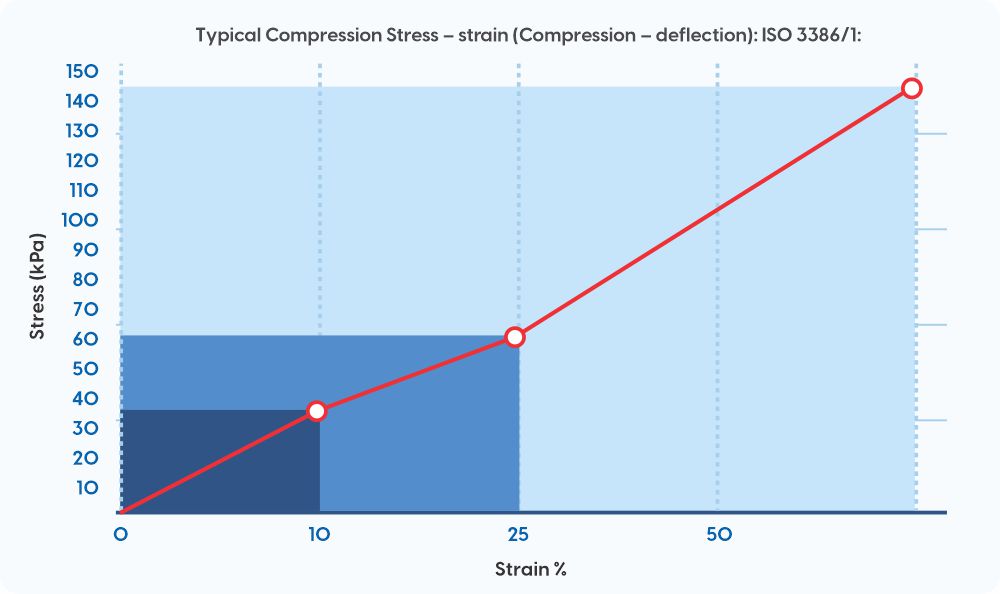

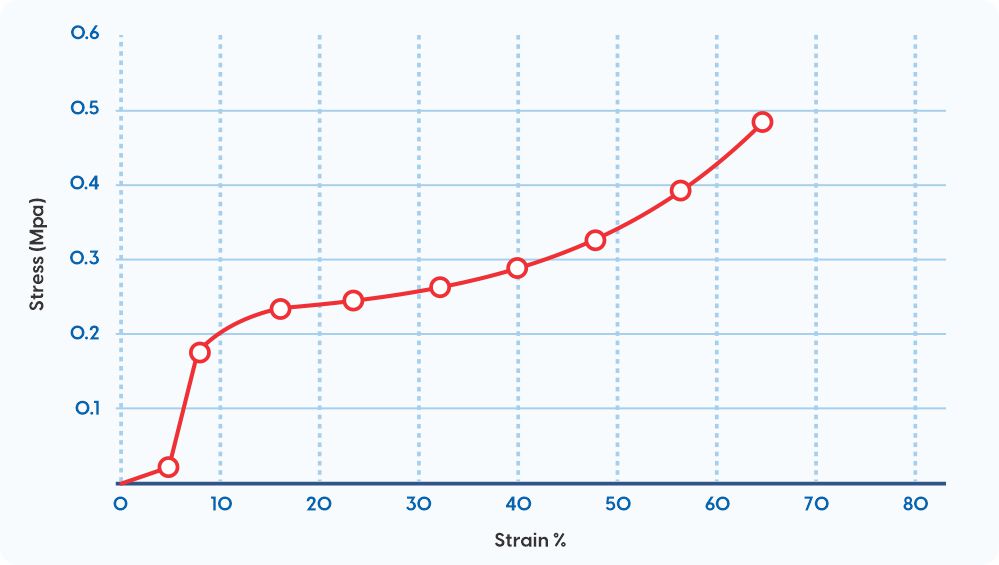

- Recovery: Can be compressed by up to 95 % of its thickness and returns to original size within minutes of release.

- Resistance: Not sensitive to decay, fungi, weak acids or alkaline solutions.

- Chemically inert.